Software

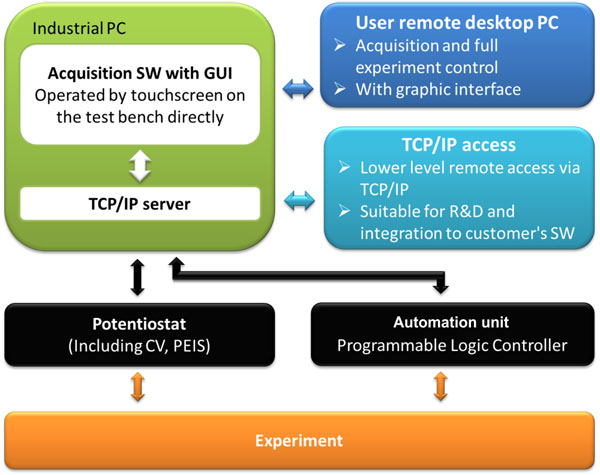

Software is designed to access in two different levels. Testing station can be controlled by our software with user friendly graphic interface enabling remote control. However, device is possible handle by direct asses to the core of software by direct commands via TCP/IP protocol and sockets which is suitable for R&D and integration to customers’s software. See the scheme below.

Fully automated and unattended operation

All functions of testing station are controlled by computer and it is ready for remote control: especially all valves, heaters, mass flow control, pressure control, humidity control. System is fully automated enables unattended operation.

Automation is realized by AIO and DIO modules and special modules enabling to control temperatures of heaters. These modules are controlled by industrial reliable robust computer where all software is integrated.

Latest version of Windows is installed. For direct on-site control of testing station the touch screen monitor and retractable keyboard with mouse are provided.

Emergency stop button to meet industry standard is taken for granted.

Safety

System contains safety procedures as nitrogen purge and emergency shut down. Working range as voltage and current of the cell, all temperature sensors are compared with safety limits that can be set. There are two levels of limits. Hydrogen leak sensor is installed.